Grafotronic – DCL²

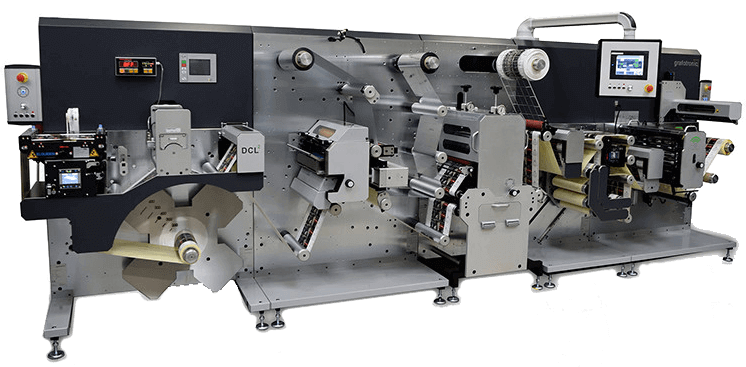

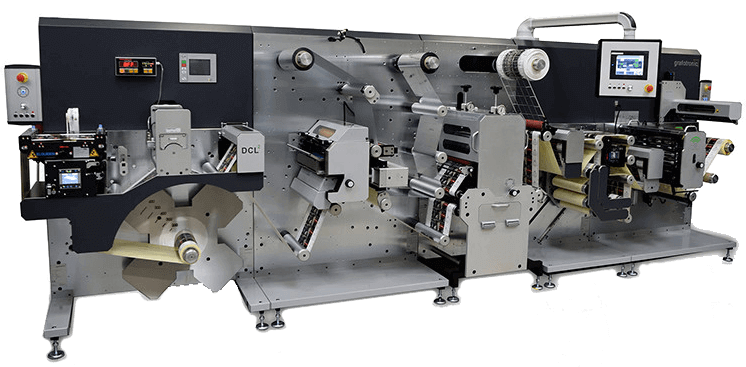

The new DCL2 Modular Digital Finishing is a fully modular converting line made for finishing of preprinted labels. The machine, which is fully servo driven, is built with the latest high-tech components available. Each module is designed for maximum performance and to cut downtime to a minimum.

Galeria

Opis maszyny

Rotary die cutting module

Heavy duty high speed die cutting units

Grafotronic Q-LOAD Quick Loading system for magnetic cylinders

Slide in / out in seconds

In register die cutting 180 m/min [590 ft/min]

Semi-rotary die cutting module

Latest technology for speeds up to 70 m /min [230 ft/min]

Cylinder size of 24″

Compensation program for existing flexible dies

Q-FLEX Flexible die quick change system

Inspection module

Module with camera housing, buffer and splice table

Waste rewind unit for multiple meters of waste

Sheeter module

Heavy duty sheeting unit with register system

Conveyor table with servo connection

QC between roll / roll roll / sheet

Slitting system

The revolutionary WIFI-SLITTING automatic knife positioning system

The System position the full set of shear cut knives within 10 seconds

Razors and standard shear knives also available

Rewind modules

Semi-turret: turret for rolls up to 420 mm [16,5″] in turret mode or 600 mm [24″] on 1 shaft

AUTOCUT automatic web cutting and start of new cycle

Single & Dual rewind: for label and mono film materials with perfect and automatic tension control For rolls up to 600 mm [24″]

Rewind shafts

No more keys or tools and multiple screws to turn to be able to change the rewind shafts

With the new Q-SHAFT you turn 1 handle 180 degrees

Q-SHAFT is quick, easy and hassle free

Najważniejsze cechy:

Unwind module

Intelligent servo unwind unit. Built in measuring system of mother roll and automatic set-up of web tension throughout the machine. Servo infeed nip station

Printing module

Spot varnish and overprinting UV/IR

Cold foil lamination

Rotary / semi-rotary versions

Pozostałe informacje

| Szerokości wstęgi | 350 mm / 450 mm / 550 mm [14″ / 18″ / 22″ |

| Maks. prędkość semirotacja | 70 m/min [230 ft/min] |

| Maks. prędkość rotacja | 180 m/min [590 ft/min] |

| Napęd | serwo |

| Maks. średnica odwijania | 750 / 1000 mm [30″ / 39″] |

| Maks. średnica nawijania | 600 mm [24″] |